What Affects the Yield of Wood Pellet Mill Equipments

For some wood pellet mill equipment users, they often operate the equipments ceaselessly in order to maximize the productivity. However, if the machines work overload without timely maintenance, oil filling, and cooling, they cannot reach the desired yield.

Then, what are the factors that affect the yield of wood pellet mill equipments?

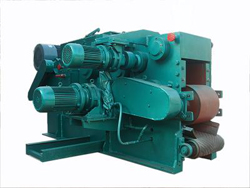

The quality of die and roller is a key element that influences productivity. The roller and die are hearts of wood pellet mill equipment, so their quality is crucial to wood pellets production. The original components or those meet quality standard are strongly recommended to use. Before using new roller and die, grind them fully and carefully for about 30-60 minutes with a mixture of bran, sand and engine oil of certain proportion. Then can put into production. Remember to keep a proper gap between the roller and die: too large will cause low yield and loose pellet density, while too small will cause abrasion to the roller and die, which will ultimately shorten their service life. During utilization, adding some oil will also increase productivity and reduce abrasion. When finished production, add some mixture of bran and edible oil into the pellet machine and press for 1-2 minutes, make sure the mixture has filled all die holes, so that the machine can be put into production directly next time. What’s more, keep an eye on the roller and die. If damage occurs, replace in time.

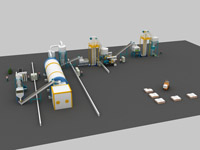

The quality of die and roller is a key element that influences productivity. The roller and die are hearts of wood pellet mill equipment, so their quality is crucial to wood pellets production. The original components or those meet quality standard are strongly recommended to use. Before using new roller and die, grind them fully and carefully for about 30-60 minutes with a mixture of bran, sand and engine oil of certain proportion. Then can put into production. Remember to keep a proper gap between the roller and die: too large will cause low yield and loose pellet density, while too small will cause abrasion to the roller and die, which will ultimately shorten their service life. During utilization, adding some oil will also increase productivity and reduce abrasion. When finished production, add some mixture of bran and edible oil into the pellet machine and press for 1-2 minutes, make sure the mixture has filled all die holes, so that the machine can be put into production directly next time. What’s more, keep an eye on the roller and die. If damage occurs, replace in time. The unreasonable configuration of automation degree, construction and mechanical property. Small scale equipments can be fed by human and the output be naturally dried. But large wood pellet plants must be collocated properly, including pulvering, mixing, deironing, mechanical conveying, and pelletizing, cooling, dedusting systems. Low voltage, low vapor pressure, imbanlance moisture ratio, and many other problems will result in insufficient yield.

The unreasonable configuration of automation degree, construction and mechanical property. Small scale equipments can be fed by human and the output be naturally dried. But large wood pellet plants must be collocated properly, including pulvering, mixing, deironing, mechanical conveying, and pelletizing, cooling, dedusting systems. Low voltage, low vapor pressure, imbanlance moisture ratio, and many other problems will result in insufficient yield.- The most important is to choose the equipment that suit you best.

Knowing the factors that affect the yield of wood pellet mill equipments can help you correctly operate the equipments and get the best yield. If you are looking for a wood pellet mill line, contact us at any time!

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!

Products

Related Topics

116th China Import and Export Fair

Are you looking for pellet mills? Do you want to……

Are you looking for pellet mills? Do you want to……

Make Your Own Wood Pellet Mill Plans

Biomass energy has sprung up everywhere because ……

Biomass energy has sprung up everywhere because ……

Homemade Pellet Press Hot Sale

Homemade pellet press has now been known to many……

Homemade pellet press has now been known to many……

Recommended Products

Copyright © GEMCO ENERGY 2001-